Our Solutions and Services.

INNOVATIVE PROCESS SOLUTIONS

Our Solutions and Services.

SEMICONDUCTOR PRODUCT ENGINEERING.

01 processing equipment

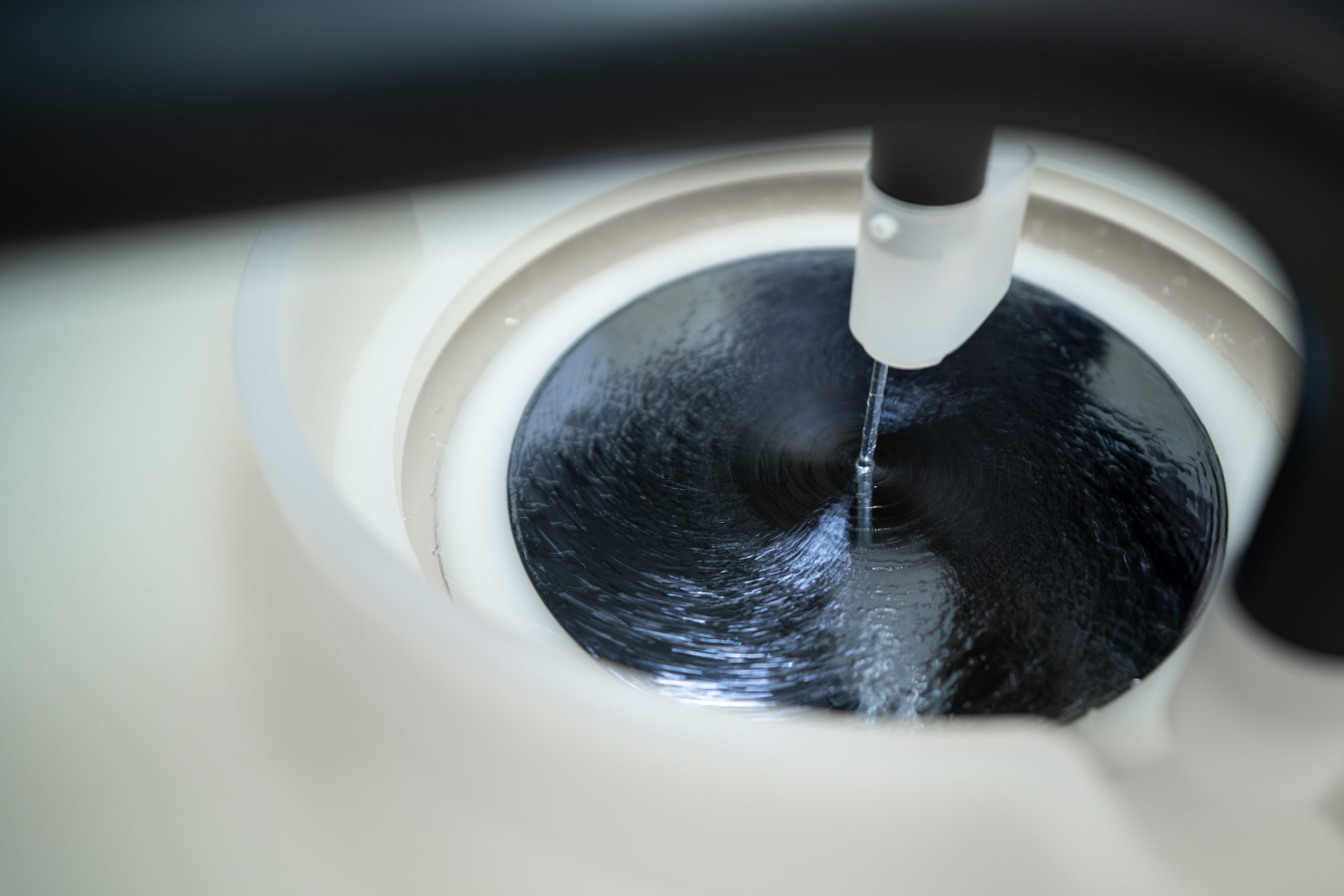

Wet Etch and Clean Equipment.

OUR EQUIPMENT PORTFOLIO COVERS SOLUTIONS FOR LOW, MEDIUM AND HIGH THROUGHPUT REQUIREMENTS TAILORED TO OUR CUSTOMER’S NEEDS.

All our wet chemical processors offer thin- and ultra-thin wafer processing capabilities and integrated metrology for substrate thickness and roughness measurements.

MG22

HIGHLY FLEXIBLE EQUIPMENT FOR MEDIUM THROUGHPUT

MG21

HIGHLY FLEXIBLE EQUIPMENT WITH LOW THROUGHPUT

02 applications

Process Solutions.

ESTABLISHING AND QUALIFYING A NEW PROCESS IS A LONG AND CAPITAL-INTENSIVE PROCESS. WE HELP OUR CUSTOMERS TO OFFLOAD A PART OF THEIR DEVELOPMENT EFFORTS IN A COST-EFFICIENT WAY.

We provide novel Wet Etch and Clean process solutions focusing on Single Wafer technology to provide our customers the best possible performance and yield.

We provide novel Etch & Clean Solutions

SURFACE CLEAN

FILM & METAL ETCH

SUBSTRATE ETCH

SUPPORTED SUBSTRATE TYPES

Si /// SiC /// GaN /// GaAs /// Al2O3 /// ZnO

4“ , 6“, 8“, 12“

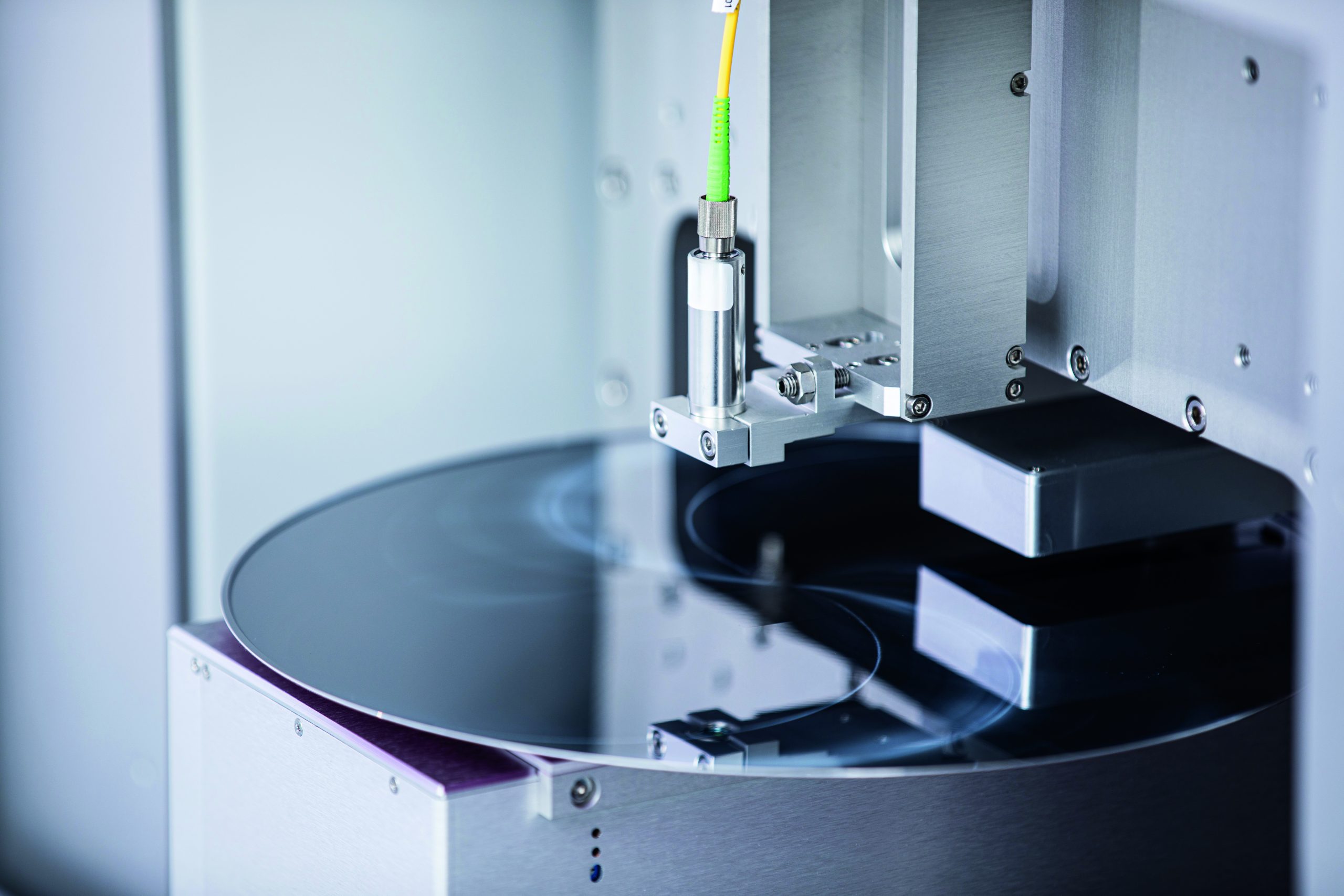

03 integrated metrology

Thickness & Roughness Measurement.

ADVANCED PROCESS CONTROL INCORPORATES REAL-TIME DATA ACQUISITION AND MANAGEMENT OF MISSION-CRITICAL PROCESS PARAMETERS THAT ARE VITAL TO ENSURE MAXIMUM RELIABILITY AND PERFORMANCE OF SEMICONDUCTORS.

For manufacturing steps that require etch and clean processes, it is critical to monitor and control parameters that affect etch uniformity, repeatability, cleaning efficiency and total thickness variation in real-time. Our equipment offers these features to maximise process performance on a within-wafer and wafer-to-wafer basis. Our inline metrology solutions provide leading-edge process control for integrated surface roughness and substrate thickness in our process equipment.

Combining wafer processing with metrology provides immediate feedback of process line stability and quality. Smart processing reduces overall operating costs and prevents out of specification incidents.